Project Portfolio

Catholic Central Field House

Learn More

Environmental Chambers

Learn More

Founders Brewery

Learn More

Gezon Medical

Learn More

Kent County 63rd District Court

Learn More

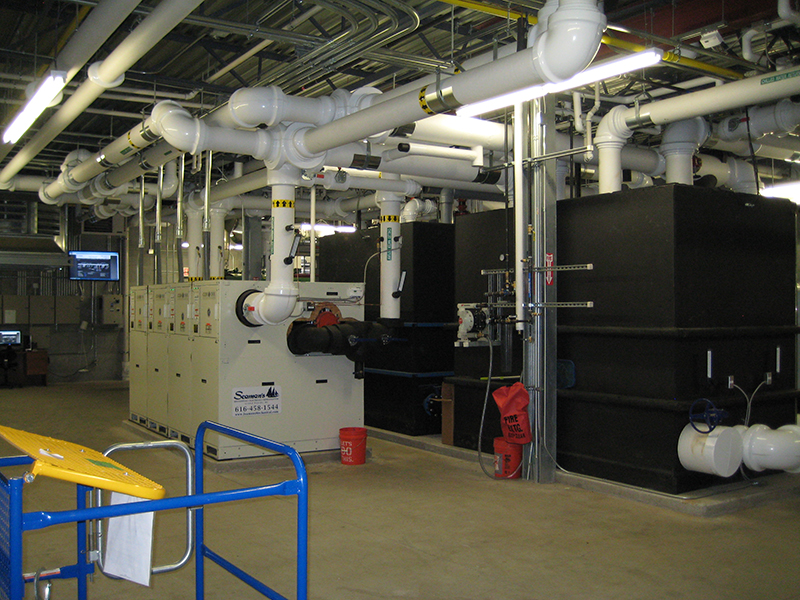

Industrial Equipment Replacement

Learn More